measuring galvanizing thickness|galvanized thickness chart : specialty store When measuring a galvanised item, if there are sections of the item which have differing steel thicknesses, each thickness range shall be treated as a separate article. The thickness ranges are dictated by AS/NZS 4680, Table 1 and . Brasil, Santos, São Paulo, Sudeste. Monte Serrat: igreja, bon.

{plog:ftitle_list}

WEBThe latest tweets from @alicedelish

zinc coating thickness measurement

This article is based on the use of magnetic gages to measure galvanizing thickness according to ASTM-A123, including the number of galvanized .Galvanizing thickness measurement. This article details the use of DeFelsko Coating Thickness Gages within the zinc galvanizing industry. It describes different types of hand held gages, the measurement process, several .

When measuring a galvanised item, if there are sections of the item which have differing steel thicknesses, each thickness range shall be treated as a separate article. The thickness ranges are dictated by AS/NZS 4680, Table 1 and .

Portable dried fruits and vegetables Moisture Meter distribute

Use the round face on the anvil to measure the wall thickness of pipe, tubing, and other curved surfaces. . Measure coatings such as paint, galvanizing, plating, and enamel and see the readings displayed on an easy-to-read digital screen. Digital Coating-Thickness GaugesGalvInfoNote Selecting Coating Thickness (Weight or Mass) for Galvanized Steel Sheet Products 1.6 REV 1.2 DEC 2017 Introduction The proper selection of coating thickness to meet a galvanized steel sheet user’s needs requires knowledge of the corrosiveness of the environment in which the product will be used. The thickness of thesteel is directly proportional to the thickness of the zinc coating. Coating thickness is an important requirement in the specification and effectiveness of hot-dip galvanizing as a corrosion protection system. However, measuring coating thickness is only one of the many specification requirements in the inspection process. The reason for this is that measuring thickness correctly and precisely is challenging. A G90 coating, for example, adds around 1.6 mils (0.0016 inches, or 42 microns) to the total thickness of the coated sheet. . Galvanized and galvannealed sheet, 55 percent aluminium-zinc alloy-coated sheet, zinc-5 percent aluminium alloy-coated sheet, and .

The magnetic thickness measurements are also non-destructive and can be used to take many readings on many articles very quickly. Details on all four methods can be found in ASTM A123, but this article only addresses the use of the magnetic thickness gages. Measuring Galvanizing Thickness Using Magnetic GagesASTM D7803: Practice for Preparation of Zinc (Hot-Dip Galvanized) Coated Iron and Steel Product and Hardware Surfaces for Powder Coating ASTM E376: Standard Practice for Measuring Coating Thickness by Magnetic-Field or Eddy-Current (Electromagnetic) Examination Methods Let's examine a few of these specifications in more detail. «

PosiTest magnetic pull-off thickness gage (banana gauge) for the non-destructive measurement of non-magnetic coatings (paint, enamel, galvanizing, metalizing, plating, etc.) on steel. Conforms to ASTM D7091/B499, ISO 2808 and others.Hot-Dip Galvanizing By Philip G. Rahrig and John Krzywicki AN OVERVIEW FOR ENGINEERS, ARCHITECTS, AND DETAILERS . the thickness loss of the hole and ensures a clean connection. On threaded assemblies with diameters greater than 1.5” (3.8 cm), it is often more practical, if design strength allows, to have .

Gauge (Ga.) is a measurement unit of the thickness of a thin material (such as sheet metal or plastic film). We often use gauges with numbers to show the thickness or diameter of materials. . the thinner the metal sheet. For example, 16 gauge galvanized steel sheet thickness is 1.6129 mm (0.0635 inches); while 18 gauge galvanized steel sheet .The PosiTector 6000 is a rugged, fully electronic coating thickness gauges use magnetic and eddy current principles to measure coating thickness on ALL metals, accurately and quickly . Measuring Galvanizing Thickness. This article details the use of DeFelsko Coating Thickness Gages within the zinc galvanizing industry. Contact the GalvInfo Center The usual criterion for determining the expected service life of zinc coatings is thickness: the thicker the coating, the longer the service life. Hot-dip galvanizing (batch or continuous), electrogalvanizing, zinc plating 1.7 mils (43µm) Zinc Spraying (metallizing) 1.9.The Elcometer range of mechanical coating thickness gauges provides cost-effective dry film thickness measurement. Mechanical Coating Thickness Gauges are suitable for working in high risk areas such as high temperature or flammable atmospheres, underwater or where the risk of explosion is high and could be triggered by the use of an electronic .

How to measure plating & galvanizing thickness. Plating thickness measurement can be done many different ways. Please see also -- • Topic 7652 "Microsection vs. XRF Method" • Topic 1164 "Thickness measurement of gold plating" • Search the site for dozens more :-)GAUGE TO THICKNESS CHART Gauge Stainless Galvanized Sheet Steel Aluminum Fraction inches (mm) inches (mm) inches (mm) inches (mm) 30 0.0125 (0.33) 0.0157 (0.40) 0.0120 (0.30) 0.0100 (0.25) 29 0.0141 (0.36) 0.0172 (0.44) 0.0135 (0.34) 0.0113 (0.29) 28 1/64 0.0156 (0.41) 0.0187 (0.47) 0.0149 (0.38) 0.0126 (0.32)

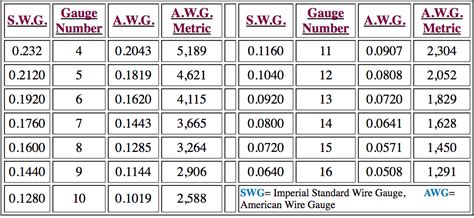

Gauge (or gage) sizes are numbers that indicate the thickness of a piece of sheet metal, with a higher number referring to a thinner sheet. . The Manufacturers' Standard Gage provides the thicknesses for standard steel, galvanized steel, and stainless steel. The Brown and Sharpe Gage, also known as the American Wire Gage (AWG), is used for .

Subtract the thickness of the shim from the measured thickness and be mindful of the additional measurement tolerance resulting from use of the shim. Indications that a probe may need service include lower than expected readings (i.e. probe tip wear), higher than expected readings (i.e. foreign material stuck on it) and erratic measurements (i .

With this Coating Thickness Measuring Device, layer thicknesses on metallic surfaces can be reliably determined. The Coating Thickness Measuring Device has a measuring range of 1500 µm. This means that the Coating Thickness Measuring Device is used, for example, in a paint shop, for incoming goods inspection or for an expert. The most practical way to measure galvanizing thickness is the non-destructive method utilizing the magnetic principle for determining coating thickness. This test is: Non-destructive Simple, fast, and inexpensive In accordance with international standards including ASTM D7091, CSA G 164-M and ISO 2808 mils = µm x 0.03937 oz/ft² = µm x 0.02316 g/m² = µm x 7.067 It’s important to remember that microns (µm) and coating grade have the same value. We can multiply 75 by 0.03937 to get required mils (2.95), multiply 75 by 0.02316 to get ounces per square feet [oz/ft²] (1.74), or multiply 75 by 7.067 to.The DPN is a progressive measure of hardness; the higher the number, the greater the hardness. Typically, the Gamma, Delta and Zeta layers are harder than the underlying steel. . The carbon, sulfur and manganese content of the steel also may have a minor effect on the galvanized coating thickness. The combination of elements mentioned above .

This variation in the galvanizing thickness can be enough to make it difficult, if not impossible, to determine the precise thickness of the liquid or powder coating. For instance, if you are trying to measure 3.0 to 5.0 mils of liquid epoxy coating galvanizing using traditional gages, the actual thickness of the galvanizing in the precise .The PosiTest DFT is the economical choice for measuring coating thickness on all metal substrates, with the same uncompromising DeFelsko quality. . This article details the use of DeFelsko Coating Thickness Gages within the zinc galvanizing industry. Application Notes. Calibration Terms - Coating Thickness Gages. This discussion provides .Precautions for coating thickness gauge to measure galvanized layer. 1. Before measurement, zero adjustment must be made on an uncoated substrate with the same base material, thickness, measurement area, and surface curvature radius as the tested sample to ensure the accuracy of the measurement; 2. In order to ensure the accuracy of the .

The specifications for hot-dip galvanizing do not set a maximum coating thickness, so there is no limit on the thickness of the hot-dip galvanized coating. However, there is a requirement the coating meets the intended use of the product, so if there are drips and runs in an area that will cause a fit problem in the parts final assembly, then . Some of the measurement techniques take advantage of the relationship between coating thickness and coating weight to measure the weight added to the steel article and, thereby, determine the coating thickness value. The most popular measurement technique for galvanized coating thickness is the magnetic thickness gauge.

Hay Moisture Meter distribute

webPost #23121 — 𝐅𝐚𝐦𝐨𝐬𝐢𝐧𝐡𝐚𝐬 💦 (@mcmelodyfamosinhas) Catalog. Ratings. Analytics. Search by posts. Telegram monitoring. 𝐅𝐚𝐦𝐨𝐬𝐢𝐧𝐡𝐚𝐬 💦. 3 Jun 2023, 06:54. https://t.me/clubfamosas. Entrem no chat do .

measuring galvanizing thickness|galvanized thickness chart